Enjoying the opportunity to observe

by Peter Huntoon I was provided the opportunity to observe the operation of an LEPE (large examining and printing equipment) press at the Bureau of Engraving and Printing Washington printing…

by Peter Huntoon

I was provided the opportunity to observe the operation of an LEPE (large examining and printing equipment) press at the Bureau of Engraving and Printing Washington printing plant on Nov. 13, 2017. It is the latest generation of machine that overprints the seals, district identifiers and serial numbers on U. S. currency and was installed in 2012. My hosts were Marketing Manager Kevin Brown, Public Affairs Specialist Tracy Garrett, and Foreman Mark Meizel.

My primary objective was to gain insights into how the machine worked in order to pass that information on to you. A particular interest I had was to learn more about the modern mismatch serial numbers that we are seeing and also to understand how selected parts of an overprint become misaligned whereas the rest of it is perfectly placed. I also wanted to see where and how star sheets and star note packs were inserted during the operation of the press.

An LEPE press is a huge, complex machine that produces remarkably consistent overprints utilizing multiple-coordinated, high-precision mechanisms. This is not to imply that the components of the machine are delicate. Quite to the contrary. The sealing and numbering mechanisms take a tremendous beating, so the machine is stout, the components heavy and manufactured from the finest steels, and the electric motors that drive it powerful.

My task was to soak up as much information as possible in a short time. What appears here is as accurate as I can relate it, but be wary because I was suffering from severe information overload during the visit, so I may muff a detail or two.

What is presented is a November 2017 snapshot. This caveat is important because technology is not standing still at the Bureau. What I observed pertaining to the LEPE press can be rendered obsolete in short order by an upgrade, retrofit or reconfiguration.

The manufacturer label on the side of the press is KBA Giori. The press I observed was set up to handle 50-subject $1 Series of 2017 Atlanta Federal Reserve notes bearing the signatures of Secretary of the Treasury Steven Mnuchin and U.S. Treasurer Jovita Carranza. The sheets are five notes wide and ten deep.

When I was there, I recorded one of the serial numbers that flashed by on a computer monitor that displays a number from the sheet being overprinted. It happened to be F26760099A. They were numbering the 5th run in the FA block.

There are two big takeaways in the following discussion.

First, numbering progresses from the high to low serial numbers within a given print run, which consists of 128,000 sheets or 6,400,000 notes. Although the numbering within a run is from the high to low serials, the runs themselves are processed sequentially from the beginning to end of the block.

Second, there are three rotating cylinders that apply the overprints, each of which is oriented horizontally. They are stacked in the machine. The top cylinder applies the green Treasury seal and black Federal Reserve district seal and black district numbers first. The middle cylinder prints the left serial numbers second. The bottom cylinder prints the right serial numbers third. Notice in this configuration that the top cylinder is bi-color, whereas the middle and bottom cylinders print only green serial numbers.

Each cylinder abuts it own inking roller. Each of them is oriented horizontally as well.

The machine is not quite the size of a semi-truck. What was amazing to me is that half of the machine is mounted on rails so that when the operators have to get at the printing mechanism, the machine splits in half, and half of it glides away, allowing an operator to walk inside with the cylinders to the right and the inking mechanisms and rollers to the left.

The machine is big, with sufficient room when split that I could comfortably stand inside to look at the print cylinders without the risk of backing into the inking rollers to ruin my clothes. It was as if I came upon a tractor-trailer rig and the driver detached the trailer so I could walk between it and the tractor.

The feedstock consists of a stack of sheets with the face side up. The sheets are removed from the top of the stack one at a time to start their journey through the press. They emerge from the press face side up with their overprints and land in an output pile in reverse order; that is, the top sheet on the input stack is the bottom sheet in the output pile.

Although the process is continuous, the freshly overprinted sheets are accumulated in batches of 100. Each group of 100 sheets consists of 5,000 notes that will come out consecutively numbered.

The highest serials assigned to each plate position are printed on the first sheet and the lowest on the 100th sheet. Consequently, the lowest numbers end up on the sheet at the top of the output pile and the highest on the sheet at the bottom.

As the group is processed, numbering progresses from high to low in each of the 50 positions.

The lowest 100 numbers for the group are assigned to the upper right position and the highest to the lower left position. Numbering on a given sheet progresses from right to left across the rows and downward through successive rows. The serial numbers increase by an increment of 100 between the successive positions on each sheet.

Once a batch of 100 sheets has accumulated, it is moved onward where the left and right selvage is cut from the sheets. Next, horizontal strips of five notes are cut from the sheets starting from the bottom up. The five-note strips continue to a banding station where five bands are simultaneously wrapped around the strips and sealed by means of heat-pressure sensitive adhesives on the bands. The strips are then cut into five individual straps of 100 banded notes. The 100-note straps are mechanically accumulated in numerical order, where they proceed to a packaging unit that first shrink-wraps bundles of packs in plastic and affixes labels on the bundles, then moves the shrink-wrapped bundles onward to a larger packaging and boxing mechanism.

The first question you should be asking in all of this is why do they employ two cylinders to print the serial numbers, the first to print the left serials on the notes and the second to print the right serials? The answer is simple. The numbering heads are so large on the LEPE presses, two of them can’t fit side-by-side to print both serials on a given note.

The numbering heads are sophisticated mechanisms wherein the left six numbers are computer driven and the right two numbers are mechanically driven.

As the press is operating, you can watch the serial number from one of the positions cycle downward on a dedicated computer monitor. After the last sheet in the group is numbered, you can hear a very audible whirring as the computer reduces the serial numbers by 5000 in all 100 number heads on the press as it sets itself up to print the next 5000 serials. Those next 5000 serials will, of course, be the next lower serials in the print run.

The configuration of the overprints differ between the denominations, yet all are printed on this machine. Handling the differences requires setup work.

They have extra cylinders that they set up to process notes for other Federal Reserve districts or other denominations for a given district. The spare cylinders allow for easy access so the operators can get at them without working in the cramped confines inside the machine. Also, setting them up externally eliminates machine down time. When needed, the externally configured cylinders are swapped for those in the press. They are heavy units, about the size of small car engines, so they are mounted on movable carriages. The one I observed was set up for a $5 or higher denomination, so the numbering heads had two prefix letters, eight numbers and one suffix letter.

The cylinder that prints the seals and district identifiers utilizes small typographic printing elements. There are 50 individual Treasury seals, 50 individual district seals, etc. Each is fastened to the cylinder by means of machine screws. Obviously, the operators need ready access in order to change these elements.

Of course, they have spare numbering heads, and I was particularly desirous of seeing one up close. Mr. Meizel removed one from a cabinet and handed it to me. It was about 5 inches long and 2.5 by 2 inches in the other dimensions. It weighed a couple of pounds, and the manufacture template read Atlantic Zeiser. Most of it consisted of the computer-driven electric motor that regulates and monitors the left-most 6 digits in the serial number. The one I held was set up for an 8-digit serial number with two prefix letters and one suffix letter. All eleven character wheels revolve around a common shaft.

Mr. Meizel advised that the prefix and suffix wheels were locked into place once set. The positions of the six highest number wheels are governed by the computer, whereas the two lowest number wheels are tripped mechanically as the cylinder rotates. I could easily trip the low numbers. I noticed what looked like two spacers to the left of the prefix letters, causing me to think there was room for two more letter wheels if needed.

What I really wanted to see were some individual character wheels. To my absolute delight, Mr. Meizel pulled out a drawer that held a large plastic tray complete with posts on which were stacked numerous spare character wheels.

The letter wheels for this machine have 13 characters around their circumference, whereas six of the number wheels have 12 and two have 10.

What I saw is summarized in Figure 2:

The characters on the wheels usually used for the Federal Reserve district letters are:

A B C D E F G H I J K L Z

The Z is used in trial work or when a Z is required elsewhere in a serial.

There are two wheels used for prefix and suffix characters. They have these characters:

A B C D E F G H I J K L *

M N P Q R S T U V W X Y blank

Notice that O and Z are missing. A blank means a non-print space on the circumference of the wheel.

The six computer-driven number wheels have 12 characters that are:

1 2 3 4 5 6 7 8 9 0 blank solid-rectangle

I specifically inquired about the purpose of the solid rectangle. I was advised that it has no specific purpose but rather is “part of the mechanical configuration.”

The two mechanically tripped number wheels have 10 characters, respectively:

1 2 3 4 5 6 7 8 9 0

Let’s look closely at the handling of star notes. Star notes function simply as place holders to maintain the proper count of notes in the finished runs. However, no one cares what the serial numbers are on those star notes or even the order in which they are inserted.

As the machine is running, star notes are inserted in two fashions. The first involves the insertion of full sheets of star notes into the stream. The second involves inserting full 100-note straps into the stream.

Let’s look first at the insertion of full sheets of star notes into the production stream.

When faults are detected by signals from the individual number heads or by a digital scanner that scrutinizes the sheets immediately after they are overprinted, the press stops and the main computer monitor flashes red with a display of the serial number and plate position where the fault occurred. The operator retrieves the last several sheets from the output pile, pages to the defective sheet, and looks at the flagged position. If there is a fault, it and any adjacent defective sheets are manually replaced with full sheets of star notes from a bin on the top of the machine. The good sheets, along with the inserted star sheet(s), are then returned to the output pile and the press restarted.

The star sheets that come from the bin on the top of the machine were of particular interest to me. It appears that the operators load 100 sheets at a time into the bin, which are obtained from the top of a stock of uncut sheets of star notes stored nearby.

Once the star sheets are in the bin, they are used from the top down. Consequently, the star sheets are consumed in numerical order from lowest to highest serials. This is opposite to the order of the sheets into which they are being inserted!

I couldn’t resist looking to see what the serials were on the star sheets in the bin. I noticed that most of the sheets in it already had been used. When I looked at the serial on the note in the upper right corner of the top sheet, I was thrilled to see that it was F00000078*. How about that! They were working through the first hundred sheets of star notes.

The sheets containing serials F00000001* through F00000077* already had been used and were buried throughout the first four runs of the FA block, with some in the current fifth run. The operators shrugged when I pointed out the low serial. Probably no one even noticed when the number 1 sheet went by. Keven Brown proudly observed that the small number of replacement sheets that had been consumed spoke well for the low rejection rate being experienced.

There was a reject bin containing a small number of rejected sheets. Those that I saw had seriously under-inked or largely missing Federal Reserve seals and numbers. They really didn’t strike me as very interesting in this setting. Clearly, they were waste. It was contagious, being immersed around all this stuff caused me to become jaded.

Now let’s look at the insertion of full straps of 100 star notes into the production stream.

When a fault is detected by the digital scanner attached to the separating equipment, the entire strap of 100 banded notes that hosts the fault is automatically shunted aside and replaced with a banded strap of star notes from a hopper. The straps from the hopper are automatically inserted into the correct location within the stream of normal straps.

The hopper contains straps that have been loaded into it that usually are in proper order, with the low serial at the top and high on the bottom. I didn’t see it happen, but it appeared that when a strap of star notes is inserted, it comes from the bottom of the hopper.

At this stage, the machine is accumulating the banded straps from the group into a bin. The first strap from the group that falls into the bin is the one with the highest serials. The strap with the lowest serials from the group lands on top. Thus, the notes in the bin come out in correct serial number order. Consequently, when successive straps of star notes are inserted into the stream, the serials on them also come out in proper numerical order because the straps with the highest serial numbers are the first to be fed into the receiving bin.

Foreman Meizel advised that the majority of rejected packs at this stage involve notes with centering problems.

There were no inspectors looking for misprints in this operation. All of that work is relegated to scanners and computers that work at lightning speed.

The numbering of notes by the LEPE machines is complicated because it is carried out in groups of 100 sheets, but the key fact is that the notes are numbered from the high to low serials both within the groups and within each press run of 128,000 sheets.

There is nothing new about numbering from the high to low serial numbers within print runs at the BEP, regardless of the vintage of the machines. The idea is that the sheets at both the input and output ends of the machine face up. The top sheet in the input pile ended up as the bottom sheet in the output pile. By numbering from high to low, the lowest number(s) came out on the top of the finished pile.

The modern numbering presses in use since 1953 numbered through the stacks of sheets, not down the columns of the individual sheets. Included are the 18-subject presses that came online in 1953, 32-subject presses introduced in 1957, and COPE presses that followed in 1971. COPE machines are still in use.

The numbering of small-size type notes printed from 12-subject plates was carried out on very ingenious 12-subject presses put in service in 1928. They also numbered from the high to low serials. However, the operation of those machines was distinctive in that they numbered the notes consecutively down the respective sides of each sheet, then separated and collated the notes before the next sheet was processed. The first half of the serial number range in a press run was assigned to the left side of the sheets and the second half to the right side.

I don’t have definitive documentation on how numbering progressed on the 4-subject Harris numbering presses first put in service in 1910 to number large-size type notes. I suspect they also numbered from high to low, because the 12-subject small note numbering machines were modeled after them. Like the 12-subject presses, the 4-subject presses numbered down the sheet, cut the notes, and collated them. When they had to number 8-subject large size sheets, they simply cut the sheets in half and fed the half sheets through the press.

The first rotary numbering machines employed at the BEP were four-subject presses that printed only serial numbers. Those machines came online in 1903 and were made by the Potter Printing Press Company. I have no idea whether they numbered from low to high or high to low.

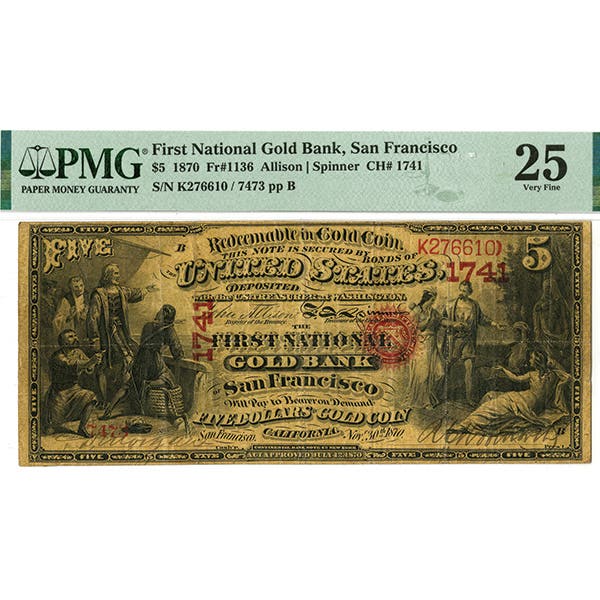

Similarly, I have seen no documentation that explains the order of the numbering of large-size national bank notes on the Potter Presses or the numbering of small-size nationals on the six-subject presses used to number them. It appears likely that numbering began at 1 and progressed to the higher serials in the case of the nationals because the national bank note sheets were numbered in small batches that often consisted of odd numbers of sheets. It would have been easier to set them up beginning with the low numbers, but this is speculation.

Believe it or not, prior to 1903, all the currency was numbered one serial number at a time using paging machines, a slew of which were operated by an army of women. The paging machines held a numbering head that the operator aligned over the note, which she then used to stamp the number into place.

This article was originally printed in Bank Note Reporter. >> Subscribe today.

More Collecting Resources

• The Standard Catalog of United States Paper Money is the only annual guide that provides complete coverage of U.S. currency with today’s market prices.

• With over 25,000 listings and 15,500 illustrations, the Standard Catalog of World Paper Money, Modern Issues is your go-to guide for modern bank notes.